Introduction

Heat shrink tube is an essential component in electrical installations, wire management, and industrial applications worldwide. As a leading B2B manufacturer, WILLELE Electric specializes in producing high-quality heat shrink tubing solutions that meet international standards and demanding industrial requirements. This comprehensive guide explores everything you need to know about heat shrink tubes, from material types and sizing to applications and installation techniques, helping you make informed decisions for your electrical projects.

What is Heat Shrink Tube?

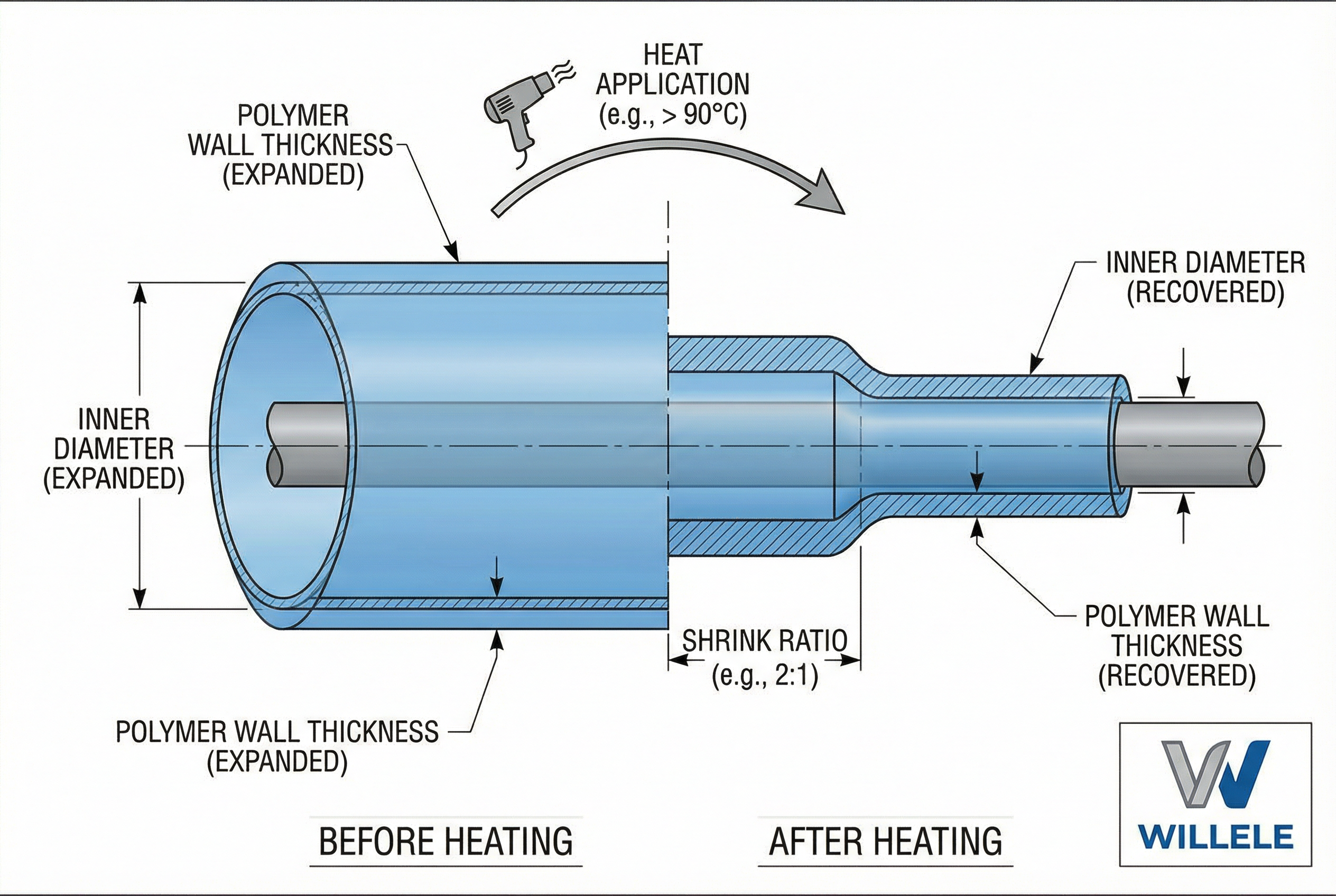

Heat shrink tube is a thermoplastic tubing that contracts radially when exposed to heat, typically reducing to 50% or less of its original diameter. This shrinking property creates a tight, protective seal around wires, cables, connectors, and other components. The material “remembers” its original extruded shape and returns to it when heated above its transition temperature, usually between 90°C and 200°C depending on the material composition.

Technical Working Principle

Heat shrink tubes are manufactured through a process called radiation cross-linking or chemical cross-linking, which creates a three-dimensional molecular structure. During manufacturing, the tubing is expanded to a larger diameter while heated, then rapidly cooled to maintain this expanded state. When heat is applied during installation, the molecular chains regain mobility and contract back to their original dimensions, conforming tightly to the underlying substrate.

Types of Heat Shrink Tubes

Understanding the different types of heat shrink tubing is crucial for selecting the right product for your application. Here’s a comprehensive comparison of the most common types:

| Type | Material Base | 収縮率 | 温度範囲 | 主な特徴 | Primary Applications |

|---|---|---|---|---|---|

| ポリオレフィン | Cross-linked PE | 2:1, 3:1, 4:1 | -55°C to 125°C | General purpose, UL listed, flexible | Wire insulation, cable bundling, identification |

| PVC | Polyvinyl Chloride | 2:1 | -20°C to 85°C | Economical, flame retardant | Low-voltage applications, color coding |

| PVDF | Polyvinylidene Fluoride | 2:1 | -55°C to 175°C | Chemical resistant, high temperature | Aerospace, military, harsh environments |

| Fluoropolymer (FEP/PTFE) | Teflon-based | 1.3:1 to 4:1 | -65°C to 200°C | Exceptional chemical resistance | High-temp electronics, chemical processing |

| 粘着裏地付き | PE with hot-melt | 3:1, 4:1 | -55°C to 110°C | Waterproof seal, strain relief | Marine, automotive, outdoor connections |

| Elastomeric | Rubber-based | 2:1, 3:1 | -75°C to 175°C | Ultra-flexible, cold resistant | Military, aerospace, extreme conditions |

Specialty Heat Shrink Variants

Dual-Wall Heat Shrink Tubes: Feature an outer polyolefin layer and inner adhesive layer, providing superior environmental sealing and moisture protection. WILLELE manufactures dual-wall tubes with adhesive activation temperatures optimized for various installation conditions.

Heavy-Wall Heat Shrink: Designed for mechanical protection with wall thicknesses up to 5mm, these tubes provide impact resistance and abrasion protection for underground cables and industrial equipment.

High-Temperature Heat Shrink: Utilizing advanced polymers like PVDF and silicone rubber, these tubes maintain their properties at sustained temperatures exceeding 175°C, essential for engine compartments and industrial heating applications.

Sizes and Specifications

Heat shrink tube sizing is critical for proper fit and function. WILLELE Electric offers comprehensive sizing options to accommodate virtually any application.

Standard Size Chart

| Supplied Diameter (mm) | After Shrinking (mm) | Recommended Cable Range (mm) | 壁厚 | Typical Applications |

|---|---|---|---|---|

| 1.5 | 0.75 | 0.5 – 1.2 | Thin (0.2mm) | Small wires, electronics |

| 3.0 | 1.5 | 1.0 – 2.5 | Thin (0.25mm) | Signal wires, sensor cables |

| 6.0 | 3.0 | 2.5 – 5.0 | Medium (0.35mm) | Power cables, connectors |

| 9.0 | 4.5 | 4.0 – 8.0 | Medium (0.4mm) | Multi-conductor cables |

| 12.0 | 6.0 | 5.5 – 10.5 | Medium (0.5mm) | Industrial wiring |

| 19.0 | 9.5 | 8.5 – 17.0 | Heavy (0.7mm) | Cable bundling, harnesses |

| 25.0 | 12.5 | 11.0 – 22.0 | Heavy (0.8mm) | Bus bars, large conductors |

| 38.0 | 19.0 | 17.0 – 35.0 | Heavy (1.0mm) | Pipeline coating, structural |

| 50.0 | 25.0 | 22.0 – 45.0 | Heavy (1.2mm) | Large cable assemblies |

Key Sizing Considerations

収縮率: The ratio between the supplied diameter and fully shrunk diameter. Common ratios include:

- 2:1 Ratio: General purpose, shrinks to 50% of supplied diameter

- 3:1 Ratio: Greater flexibility in sizing, accommodates irregular shapes

- 4:1 Ratio: Maximum versatility, ideal for transition areas and branching

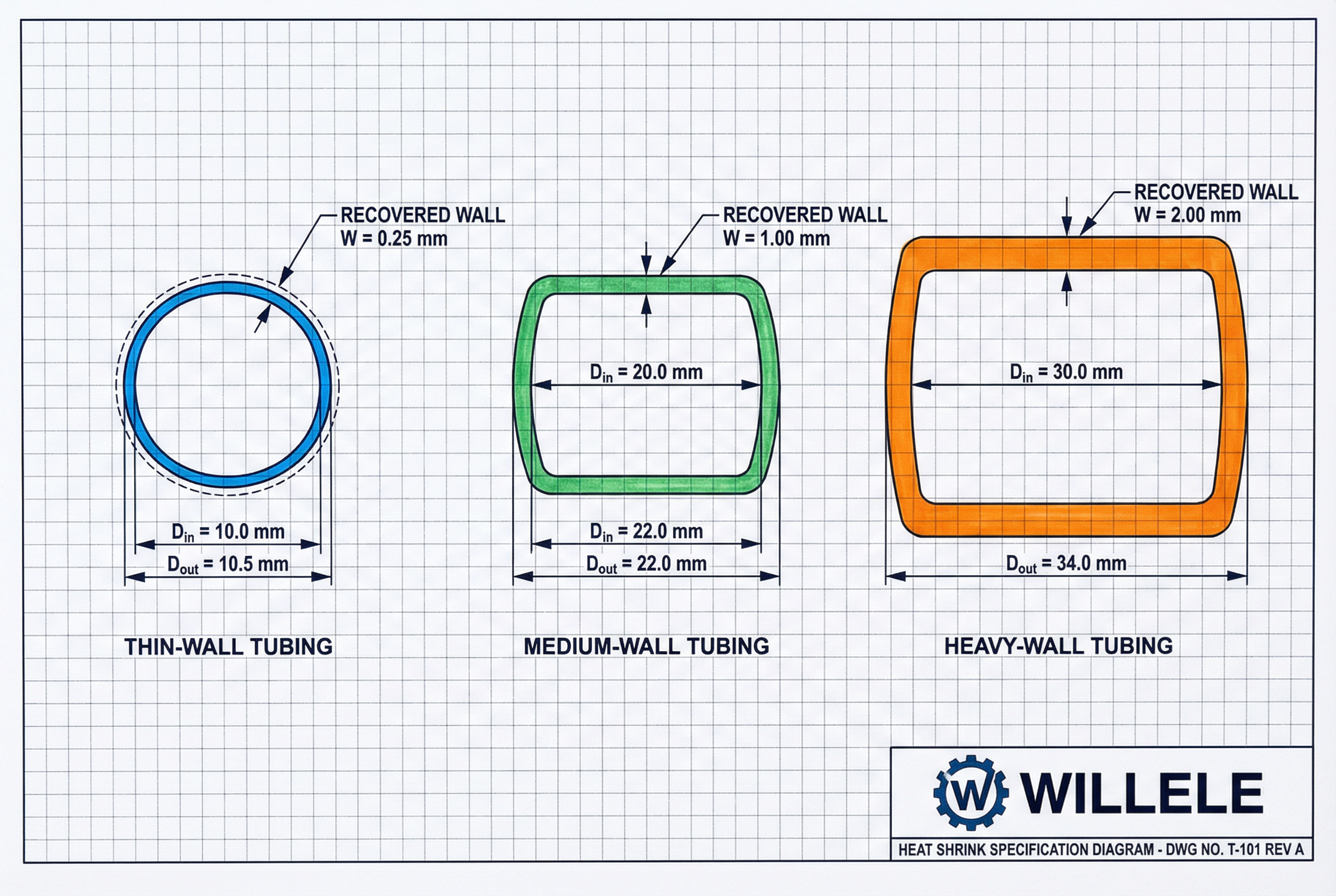

Wall Thickness Classifications:

- Thin-wall (0.2-0.4mm): Lightweight electrical insulation

- Medium-wall (0.4-0.8mm): Standard industrial applications

- Heavy-wall (0.8-2.0mm): Mechanical protection and harsh environments

Applications and Use Cases

Heat shrink tube technology serves diverse industries and applications. WILLELE Electric solutions are deployed across multiple sectors worldwide.

Primary Application Categories

電気絶縁: Providing dielectric strength and voltage resistance for wire terminations, splices, and repairs. Heat shrink tubes offer reliable insulation with voltage ratings from 600V to 69kV depending on wall thickness and material.

環境保護: Sealing connections against moisture, chemicals, UV radiation, and contaminants. Adhesive-lined variants create waterproof barriers with IP67/IP68 ratings suitable for marine and outdoor installations.

機械的保護: Shielding cables from abrasion, impact, and crushing forces in industrial settings. Heavy-wall tubes protect against sharp edges, vibration, and mechanical stress.

Identification and Organization: Color-coded tubing enables systematic wire identification and cable management. WILLELE offers standard colors (black, red, blue, yellow, green, white, clear) plus custom colors for specific marking requirements.

ストレイン・リリーフ: Providing stress relief at cable entry points, connector boots, and transition zones to prevent wire fatigue and breakage.

Industry-Specific Applications

| Industry | Common Applications | Recommended Specifications |

|---|---|---|

| 自動車 | Wire harness protection, sensor cables, battery terminals | Adhesive-lined, -40°C to 125°C, oil resistant |

| Aerospace | Avionics wiring, engine sensors, fuel line protection | MIL-SPEC qualified, lightweight, flame retardant |

| 電気通信 | Fiber optic splicing, antenna connections, tower installations | UV resistant, weatherproof, color-coded |

| Marine | Navigation systems, bilge pumps, underwater connectors | Waterproof (IP68), salt fog resistant, flexible |

| 工業生産 | Motor leads, control panels, automation systems | High temperature, chemical resistant, heavy-wall |

| Renewable Energy | Solar panel connections, wind turbine wiring, battery banks | UV stable, extreme temperature, long service life |

Selection Guide

Choosing the correct heat shrink tube requires evaluating multiple factors. Use this comprehensive selection matrix:

Selection Criteria Table

| Selection Factor | Evaluation Questions | Key Specifications to Review |

|---|---|---|

| Operating Temperature | What are min/max ambient temperatures? | Continuous operating range, thermal index |

| Environmental Exposure | Indoor/outdoor? Chemical exposure? UV? | IP rating, chemical resistance, UV stability |

| Mechanical Requirements | Abrasion? Impact? Flexibility needed? | Wall thickness, tensile strength, elongation |

| 電気的特性 | Voltage level? Dielectric strength required? | Voltage rating, dielectric breakdown, tracking resistance |

| Size and Fit | Cable diameter? Irregular shapes? | Shrink ratio, recovered diameter, length |

| Regulatory Compliance | Industry standards? Certifications needed? | UL, CSA, MIL-SPEC, RoHS, REACH compliance |

| Application Method | Heat gun? Oven? Field installation? | Shrink temperature, shrink time, installation tools |

| Service Life | Expected duration? Maintenance access? | Aging properties, warranty period, replacability |

Material Selection Decision Tree

- Temperature < 85°C + Cost-sensitive → PVC Heat Shrink

- Temperature 85-125°C + General purpose → Polyolefin Heat Shrink

- Temperature 125-175°C + Chemical exposure → PVDF Heat Shrink

- Temperature > 175°C + Extreme conditions → Fluoropolymer Heat Shrink

- Waterproofing required + Outdoor → Adhesive-lined Heat Shrink

- Extreme flexibility + Low temperature → Elastomeric Heat Shrink

Installation Best Practices

Proper installation ensures optimal performance and longevity of heat shrink tube applications.

Pre-Installation Preparation

Surface Preparation: Clean all surfaces thoroughly to remove oil, dirt, oxidation, and moisture. Use appropriate solvents (isopropyl alcohol for most applications) and allow complete drying before installation.

Tube Selection Verification: Confirm the supplied diameter is 20-30% larger than the substrate diameter for standard applications. For adhesive-lined tubes, ensure 15-25% clearance to allow adhesive flow.

Cutting: Use sharp cutters to achieve clean, square cuts. Recommended cut length is substrate length plus 10-20% overhang on each side for complete coverage.

Heat Application Techniques

Heat Gun Method: Most common for field installations. Maintain 150-200mm distance, apply heat evenly using circular motion, starting from the center and working toward ends to eliminate air pockets. Typical shrink time: 30-90 seconds depending on diameter.

Oven Method: Ideal for production environments. Preheat oven to manufacturer-specified temperature (typically 150-180°C for polyolefin). Process time: 2-10 minutes depending on size and quantity.

Torch Method: Use with caution for large diameter tubes. Maintain constant motion to prevent overheating. Propane torches work well but require operator skill.

Quality Verification

Post-installation inspection criteria:

- Complete shrinkage with no bridging or air gaps

- Uniform appearance without wrinkles or bubbles

- Adhesive (if applicable) visible at tube ends

- No discoloration indicating overheating

- Proper strain relief and mechanical support

- Electrical continuity and insulation resistance testing

Common Installation Mistakes to Avoid

- Overheating causing material degradation or adhesive charring

- Insufficient heating leaving incompletely shrunk sections

- Contaminated surfaces preventing adhesive bonding

- Tube too short causing inadequate coverage

- Rapid heating causing bubbling or splitting

- Installing over sharp edges without protection

Frequently Asked Questions

Q: What is the difference between 2:1 and 3:1 shrink ratio tubes?

A: The shrink ratio indicates how much the tube contracts. A 2:1 tube shrinks to 50% of its supplied diameter, while a 3:1 tube shrinks to 33%. Higher ratios (3:1, 4:1) offer greater sizing flexibility and are better for irregular shapes or when exact cable dimensions are unknown. WILLELE recommends 2:1 for standard applications and 3:1 or 4:1 for repair work or varied cable sizes.

Q: Can heat shrink tube be reused or removed?

A: Heat shrink tubes cannot be “un-shrunk” and reused. Once heated and shrunk, the molecular structure has returned to its original state. Removal requires cutting the tube lengthwise and peeling it away. For applications requiring removability, consider using cold shrink tubes or reusable cable management solutions instead.

Q: How do I choose the right size heat shrink tube?

A: Measure the largest diameter of your substrate (cable, connector, or component). Select a tube with a supplied diameter 20-30% larger than this measurement. For example, a 10mm cable requires approximately 12-13mm supplied diameter tube. Always verify the recovered (shrunk) diameter is smaller than your substrate to ensure proper fit.

Q: What temperature is needed to shrink heat shrink tubing?

A: Most polyolefin heat shrink tubes begin shrinking at 90-100°C and fully shrink at 120-140°C. PVC tubes shrink at 70-90°C, while high-temperature materials like PVDF require 170-180°C. Always follow manufacturer specifications. WILLELE heat shrink tubes include temperature guidelines printed on packaging and technical datasheets.

Q: Are heat shrink tubes waterproof?

A: Standard single-wall heat shrink tubes provide moisture resistance but not complete waterproofing. For waterproof applications, use adhesive-lined (dual-wall) heat shrink tubes. The inner adhesive layer melts during heating and creates a complete environmental seal rated to IP67 or IP68 standards. WILLELE manufactures marine-grade adhesive-lined tubes specifically for underwater and harsh environment applications.

Q: How long does heat shrink tube last?

A: Service life depends on material type, environmental conditions, and application. Polyolefin tubes typically last 10-20 years in indoor applications, 5-10 years outdoors with UV exposure. PVDF and fluoropolymer tubes can exceed 20-30 years even in harsh conditions. WILLELE heat shrink tubes are manufactured with UV stabilizers and anti-oxidant additives to maximize longevity.

About WILLELE Electric: As a leading B2B manufacturer of electrical components, WILLELE Electric specializes in producing premium heat shrink tubes and cable management solutions for industrial, commercial, and specialized applications worldwide. Our products meet international standards including UL, CSA, and MIL-SPEC certifications. For technical specifications, custom solutions, or bulk ordering information, contact our engineering team to discuss your heat shrink tube requirements.